Additives and functional fillers

In addition to our core markets (plastics, rubber, paints, coatings, lubricants, life sciences: pharma, nutrition, cosmetics) we supply many other industries:

- Agrochemical industry

- Automotive industry

- Chemical industry

- Dental industry

- Electronics industry

- Beverage industry

- Foundry and refractory industry

- Glass and ceramics industry

- Leather and textile industry

- Metallurgy

- Paper and pulp industry

and many more.

Here we are partners for the supply of various raw materials such as additives and additive preparations, industrial minerals, processing aids, process chemicals, polymer raw materials, ingredients, functional fillers and more.

For more information, call us at +49 40 44197-0, send us an E-Mail or use our inquiry form.

Detailed information on some selected raw materials:

We are specialized in marketing rare earths and their compounds, zirconium products (trademarks: LUVOZIRC®, Zircosil®) and further speciality chemicals.

We pool a uniquely broad range of raw materials for many different applications and markets. The diversity of the possible applications for our products reflects the width of our supply program.

For every raw material requirement, we develop a high quality, reliable and long-term solution. With our supply partners, mostly manufacturers of specialty raw materials, we develop an effective, transparent and cost-effective access to the markets relevant for you.

Learn more!

We supply you with thermoplastic materials in powder form. These specialities are modified thermoplastics with particle sizes of less than 100 μm, which are employed in various applications like laser sintering for the generative production of plastic parts.

Learn more!

We supply you with thermoplastic materials in powder form. These specialities are modified thermoplastics with particle sizes of less than 100 μm, which are employed in various applications like electrostatic powder coating of metals.

Learn more!

Diatomaceous earth, also known as Kieselgur, consists of the very fine silicon skeleton of dead diatoms. Because of its natural structure, diatomaceous earth has a very large surface, is chemically inert and has a very high absorption capacity. We offer natural diatomaceous earth whose content of crystalline silica is < 0.1%, calcined diatomaceous earth and flux-calcined diatomaceous earth (fluxing agent: sodium carbonate). We also have high-purity diatomaceous earth in our product portfolio which complies with USP/NF requirements.

Our diatomaceous earth mainly comes from deposits in the USA, Mexico and Spain.

Applications:

Life science applications

Our coarse-grained diatomaceous earth grades are very well suited for the use as peeling particles in creams. The grades tested in accordance with USP/NF are the ideal filling material for food supplements, particularly tablet pressing, because of their high SiO2 content of 89-99%.

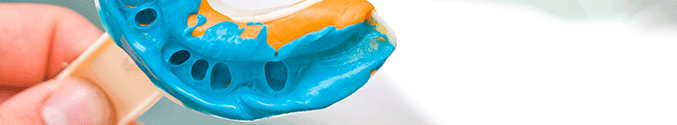

Dental impression material

Because of its high water absorption capacity of approximately 200 g/l, our diatomaceous earth products guarantee rapid mixing behaviour of the impression mass and short setting phases.

Paper industry

Diatomaceous earth products with a very high Blue Light Reflectance of approximately 95, high water absorption capacity of > 200 g/l and a surface (BET) of around 2 m²/g are extremely well suited for the use as functional fillers, among other things for the production of decorating paper.

Insecticides

The sharp-edged diatom structures cut their way through the exoskeleton of, for instance, ants which then dry out. Our natural diatomaceous earth grades with a crystalline silica content of < 0.1% are safe for children and pets, too.

Catalyst carriers

Our natural, uncalcined diatomaceous earth products with a low specific content of Al2O3 and Fe2O3 are extremely well suited for the use as catalyst carriers, for instance for nickel, cobalt, copper, sulphuric acid and also for the food industry (fat catalysts).

Refractory industry

Our heat-resistant, very light diatomaceous earth grades with an apparent density of approximately 120-140 g/l are ideal functional fillers for the production of refractory materials, heat insulating boards and fireproof boards.

Centrifugal casting

By means of defined particle distribution with an average size of approximately 8 µ, our readily calcinated diatomaceous earth grades are excellent inert materials for centrifugal casting.

Your contact: Nicola Hintze, Tel.: +49 40 44197-334, Nicola.Hintze(at)lehvoss.de

Perlite is a volcanic obsidian rock that contains 2-5% bound water. Chemically speaking, it is an aluminium silicate which is almost as inert as silicic acid. When heated, perlite expands into very light, cellular, spherical particles. In expanded, unmilled form perlite has proven its worth as an insulation material, for instance, for tanks. Because of its thermal and acoustic insulation properties, it is a popular light, inert filler in the building material industry. In milled form perlite is primarily used as a carrier, among other things, for pesticides.

Our perlite grades are mainly produced in France, Spain and Italy from Turkish ore. Applications are:

Plaster and mortar

Because of their low apparent density of approx. 55 g/l and their excellent thermal and acoustic insulation properties, our expanded unmilled perlite grades are ideally suited as aggregates for plaster and mortar, and as extenders and absorption agents.

Carrier material for crop protection agents

Given their high absorption capacity of > 200 % by weight, our inert perlite grades are excellent carrier materials for insecticides, fungicides and fertilisers.

Your contact: Nicola Hintze, Tel.: +49 40 44197-334, Nicola.Hintze(at)lehvoss.de

Our calcium silicate is produced from diatomaceous earth in the USA. It is an adsorptive, synthetic silicate with an SiO2:CaO ratio of approximately 1:3. Applications are:

Dry liquid

Thanks to their very high absorption capacity (water absorption: approximately 550 % by weight, oil absorption: approximately 450 % by weight), together with a very large surface (BET) of approximately 120 m²/g our calcium silicates are excellent functional fillers, for instance for the tyre industry, particularly as melamine resin carriers.

Life science

Our calcium silicate tested in accordance with USP/NF is ideally suited as an anti-blocking agent for instance in powder and eye shadow.

Your contact: Nicola Hintze, Tel.: +49 40 44197-334, Nicola.Hintze(at)lehvoss.de

Information about our products Talc and Wollastonite can be found here!

Hollow ceramic microspheres are extremely resistant hollow spheres, which are formed under the exposure of extreme heat. Temperatures over the relevant melting points are required to achieve a ceramic melting. Drops with a hollow are formed as a result of the subsequent rapid cooling process. The OMEGA-SPHERES® formed in this way are refined and fractionated in subsequent processes, thus being a high-quality raw material in your formulations.

The spheres we provide are produced at various production sites for global availability. Globally produced standard types are manufactured in the Ukraine and Germany. Special types are produced in Germany. There are further suppliers in Europe and throughout the world.

OMEGA-SPHERES® W

Hollow ceramic microspheres are extremely resistant hollow spheres, which are formed under the exposure of extreme heat. Temperatures over the relevant melting points are required to achieve a ceramic melting. Drops with a hollow are formed as a result of the subsequent rapid cooling process. The OMEGA-SPHERES® formed in this way are refined and fractionated in subsequent processes, thus being a high-quality raw material in your formulations.

The spheres we provide are produced at various production sites for global availability. Globally produced standard types are manufactured in the Ukraine and Germany. Special types are produced in Germany. There are further suppliers in Europe and throughout the world.

OMEGA-SPHERES®

Hollow ceramic microspheres are extremely resistant hollow spheres, which are formed under the exposure of extreme heat. Temperatures over the relevant melting points are required to achieve a ceramic melting. Drops with a hollow are formed as a result of the subsequent rapid cooling process. The OMEGA-SPHERES® formed in this way are refined and fractionated in subsequent processes, thus being a high-quality raw material in your formulations.

The spheres we provide are produced at various production sites for global availability. Globally produced standard types are manufactured in the Ukraine and Germany. Special types are produced in Germany. There are further suppliers in Europe and throughout the world.

THERMO-SPHERES

The THERMO-SPHERES are special hollow ceramic microspheres which are optimised for the field of thermal insulation. The optimised particle size range includes hollow ceramic microspheres to increase the effective surface for insulation. The mixture that results in this way better exploits the cavities than a standard type, helping the application to develop a higher protective function.

Micropearl are spherical, organic microbeads which can be expanded under the influence of heat into very low density flexible hollow spheres. The shell of the spheres consists of a thermoplastic copolymer into which a short-chain hydrocarbon is encapsulated. Depending on process conditions, different grades are available with expansions in the range of 100 - 250 °C. The thermally expansible hollow microspheres are used as a physical blowing agent wherever low density and high compressibility/flexibility are essential. Matting and anti-slip properties further enhance the performance spectrum of this interesting product class.

Your contact: Christian Pfichner, Tel.: +49 40 44197-479, chp(at)lehvoss.de

Solid aluminium silicate spheres

A solid aluminium silicate sphere is an industrial ceramic product with a spherical shape. It is formed through melting and subsequent condensation in a cooling chamber. The optimal spherical shape is created in the initial seconds in an apparent state of weightlessness. The shape is then maintained by increasing the viscosity during the cooling process.

The spherical particles formed by this process are then classified and refined into homogeneous raw materials for our customers’ use. The material is specifically characterised by low oil absorption values and good processing properties. When used in cement-based systems, solid aluminium silicate spheres also have a hydraulic effect and improve the strength of the finished products. Together with the spherical shape, the high degree of hardness helps to modify surfaces for extreme mechanical demands and stresses.

OMEGA-SIL

As a solid aluminium silicate microsphere, OMEGA-SIL combines advantageous product properties such as low surface area, high degree of hardness and spherical effects for use in virtually any application. Because of the optimal geometric shape of a sphere OMEGA-SIL makes it possible to use the ball bearing effect, thus improving processing properties. This spherical form also increases the packing density for optimal

Ceramic foams are manufactured in various ways. There is a strong distinction in both the raw materials and the production procedure. The foaming agents used and the surrounding ceramic phase are a mark of sustainability and ecological thinking. The foams are fractionated and refined after swelling, in order to be used in a multitude of applications as a high-quality industrial product.

LITHO-BUBBLES

LITHO-BUBBLES are used in the field of ecological raw materials. The special foaming process is expanded by water in a molten ceramic, making it particularly energy-saving and environmentally-friendly. Due to the carefully selected raw materials, a material is developed which has particularly low energy costs and carbon dioxide emissions. These properties make LITHOBUBBLES an ecologically meaningful raw material with an excellent energy balance.

Hollow glass spheres are produced in a process similar to our hollow ceramic microspheres. The standardised glass is transformed into a molten mass and transferred to a cooling chamber using a mist spray, which allows the material to solidify in this manner. The drop formation allows the material to expand to have a cavity, which has a strong acoustic and thermal insulating effect.

We recommend SPHERICEL types for use in aqueous systems, as these have an effective chemical composition against the attack of hydroxide ions.

Q-CEL®

Q-CEL® are hollow glass microspheres that serve as functional lightweight fillers, characterized by excellent mechanical stability.

The various Q-CEL®-types differ in density, particle size and strength which makes it possible to find special Q-CEL®-qualities for specific applications and requirements.

Q-CEL® is a commercial product and trademark of the PQ Corporation, which we distribute exclusively in Germany, Austria and Switzerland.

SPHERICEL®

SPHERICEL® are Hollow glass microspheres that serve as functional lightweight fillers, characterized by excellent mechanical stability.

The various SPHERICEL®-types differ in density, particle size and strength which makes it possible to find special SPHERICEL®-qualities for specific applications and requirements.

SPHERICEL® is a commercial product and trademark of the PQ Corporation, which we distribute exclusively in Germany, Austria and Switzerland.

OMEGA-BUBBLES© C – ultra white

OMEGA-BUBBLES® C are multicellular expanded glass granules. The high whiteness can help to reduce the addition of titanium dioxide in cementitious formulation. For aesthetic applications like acoustic construction or ceilings the ultra-white lightweight fillers meet today's spirit of time. OMEGA-BUBBLES® C being based on selected recycled glass. Using these products is sustainable and environmentally friendly and can reduces your green CO2 footprint in later disposal issues. OMEGA-BUBBLES® C are available in the grain sizes customary on the market for the construction and insulation industry.

OMEGA-BUBBLES© D – grey

OMEGA-BUBBLES® D are multicellular expanded glass granules with greyish color. They represent a cheaper alternative in all cementitious applications, where a very pure white brightness is not necessary. The OMEGA-BUBBLES® D are sustainable and also based on selected recycled glass. Using them is environmentally friendly and can help to reduce your green CO2 footprint in later questions of mixed disposal. OMEGA-BUBBLES® D are available in the grain sizes customary on the market for the construction and insulation industry, comparable to others on the market.