LEHVOSS presents its comprehensive Smart Resourcing concept at the K2025 plastics trade fair as a response to the complex challenges of the plastics industry. The Smart Resourcing concept enables customers to find the optimal combination of performance, economic efficiency, and sustainability for their specific requirements. This flexible system adapts precisely to individual project requirements and offers suitable solutions at attractive prices.

New: Metal Replacement with Recycled Raw Materials

As part of K 2025, LEHVOSS aims to present its expanded business strategy, which under the guiding theme "Smart Resourcing" complements the company's proven high-performance plastics portfolio with intelligent solutions based on recycled plastics for metal replacement. “LEHVOSS delivers high performance – that remains unchanged,” stresses Dr. Thomas Oehmichen. “What’s new: With LUVOTECH eco, we now also provide demanding materials for metal replacement based on recycled raw materials, enabling our customers to pursue smart economic resource management.”

Portfolio Expansion Offers Multiple Benefits for Customers

• Secure and new sourcing solutions

• Diversification of supplier portfolio

• Competitive conditions for metal replacement materials on an eco-basis

• Materials with exactly the required performance characteristics – without over- or under-specification

• Planning security through consistently high-quality standards and reliable delivery

Innovative Product Highlights and Exhibits at the Trade Fair Stand

The Compounds business unit of LEHVOSS once again presents itself at this year's K trade fair as a pioneer for innovative and sustainable polymer solutions in the spirit of "Smart Resourcing." The focus of the trade fair appearance is on practical exhibits that impressively demonstrate the performance of the LUVOCOM and LUVOTECH eco types used.

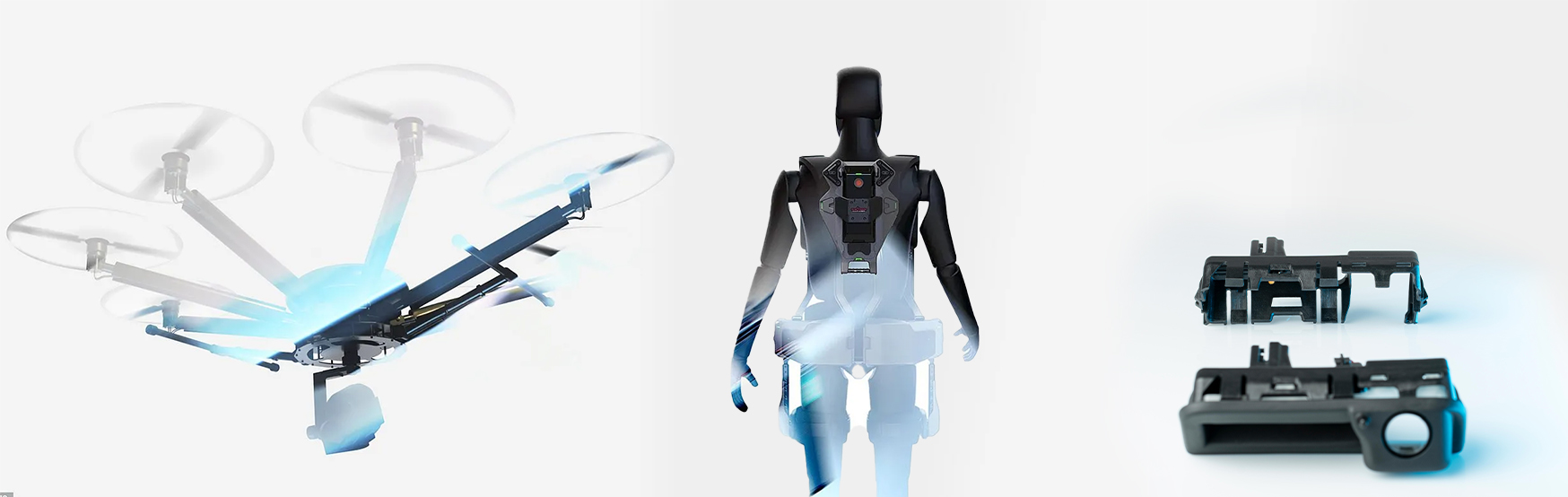

Exoskeleton: Price attractiveness and top performance with high quality standards and mechanical stability. Humanoid robots and advanced exoskeletons are rapidly growing applications that will significantly influence the working world. Using a modern exoskeleton, LEHVOSS demonstrates its high competence in the field of structural and tribologically tailored materials. The intelligently constructed components consist of metal replacement materials and tribologically modified LEHVOSS plastics. Some of the materials are additionally based on industrial recyclates.

Drones: Technically high-quality materials in cost-optimized solutions. Another trade fair highlight is autonomous drones whose components were significantly manufactured from LEHVOSS compounds. These drone-specific solutions illustrate the versatility and process reliability of LUVOCOM and LUVOTECH eco materials in the field of lightweight construction and functional integration.

The trade fair stand is complemented by additional functional components made from LUVOTECH eco types that are used in various industries. Visitors can expect a clear presentation of materials that combine forward-looking applications and sustainable value creation.

Benchmark in All Compound Areas

LUVOCOM: Compounds that are specifically developed for customer requirements, particularly for outstanding performance properties. They are used in demanding industries such as automotive, aerospace, electronics, or medical technology.

LUVOTECH: Proven standard products, such as PA66/PPA GF, CF Compounds or LCP Compounds from LEHVOSS, are characterized by cost-effective prices, fast delivery times, and outstanding personal service. Direct access to personal contact is part of the service.

LUVOTECH eco: PA6, PA66, PBT, PC/ABS, PPS GF, LCP and PEEK alternatives with different recyclate contents. LUVOTECH eco compounds are characterized by highest property consistency and high performance, are attractively priced and simultaneously sustainable.

LUVOCOM LFT: In addition to cost-optimal alternatives for standard market LFT materials, e.g., based on PA66, PA66/6 and PA66-6I/X, LEHVOSS offers additional technically demanding LFT compounds, e.g., based on PA410, PA11.

3D Printing - The New Dimension: 250,000 Pieces in Record Time

Until now, 3D printing has hardly played a role in industrial series production. Until now. LEHVOSS has selected materials with OEMs that are technically and price-optimized for part production in 3D printing farms – and have been certified. This means that orders with quantities up to 250,000 pieces can now be processed in 3D printing. Quickly and cost-effectively.

The new dimension of production speed, price, and component performance has tangible advantages: No time-consuming and expensive production of injection molding tools, and no warehousing. Additionally, delivery security increases, as in case of a supplier failure, seamless switching to another supplier is possible.

Foto: Exciting applications await visitors at the LEHVOSS stand

Photo: Dr. Thomas Oehmichen, Partner and Managing Director of the LEHVOSS Group