Carbon blacks

Thanks to its reinforcing properties, carbon black is an indispensable part of the rubber industry. With our range of furnace, thermal and special carbon blacks we fully cover all areas of application.

Furnace blacks

These types of carbon black are known as the standard rubber blacks and meet the vast majority of the market demand. In addition to the internationally valid ASTM classification, a further distinction is made between highly active, active and semi-active carbon blacks.

Thermal blacks

As an inactive carbon black, thermal black makes it possible to achieve high levels of filling and has a positive influence on the permanent set characteristics.

Recommended applications for ASTM carbon blacks

| Application in rubber | N115 | N134 | N220 | N234 | N326 | N330 | N339 | N347 | N375 | N539 | N550 | N650 | N660 | N772 | N990 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tyres | |||||||||||||||

| High-performance racing treads | ● | ● | ● | ||||||||||||

| Car treads | ● | ● | ● | ● | ● | ||||||||||

| Truck treads | ● | ● | ● | ● | ● | ● | ● | ||||||||

| Inner liners | ● | ● | ● | ||||||||||||

| Carcass | ● | ● | ● | ● | ● | ● | ● | ||||||||

| Technical rubber goods | |||||||||||||||

| V-belts and timing belts | ● | ● | |||||||||||||

| Hoses and manifolds | ● | ● | ● | ● | ● | ● | |||||||||

| Gaskets | ● | ● | ● | ● | ● | ● | |||||||||

| Window and door seals | ● | ● | ● | ||||||||||||

| O-rings and packing washers | ● | ● | ● | ● | ● | ||||||||||

| Windscreen wiper blades | ● | ● | ● | ● | |||||||||||

| Engine bearings | ● | ● | ● | ● | |||||||||||

| Oscillation dampers | ● | ● | ● | ● | ● | ||||||||||

| Solid tyres | ● | ● | ● | ● | ● | ||||||||||

| Shoe soles | ● | ● | |||||||||||||

| Fuel hoses | ● | ● | |||||||||||||

| Roofing felt | ● | ● | ● | ||||||||||||

| Conveyor belts | ● | ● | ● | ● | ● | ● | ● | ||||||||

| Cable sheathing | ● | ● | ● |

Special carbon blacks with tailor-made properties

These products stand out from the standard ASTM carbon blacks principally because of their high purity as indicated by a low sulphur content and low sieving residue.

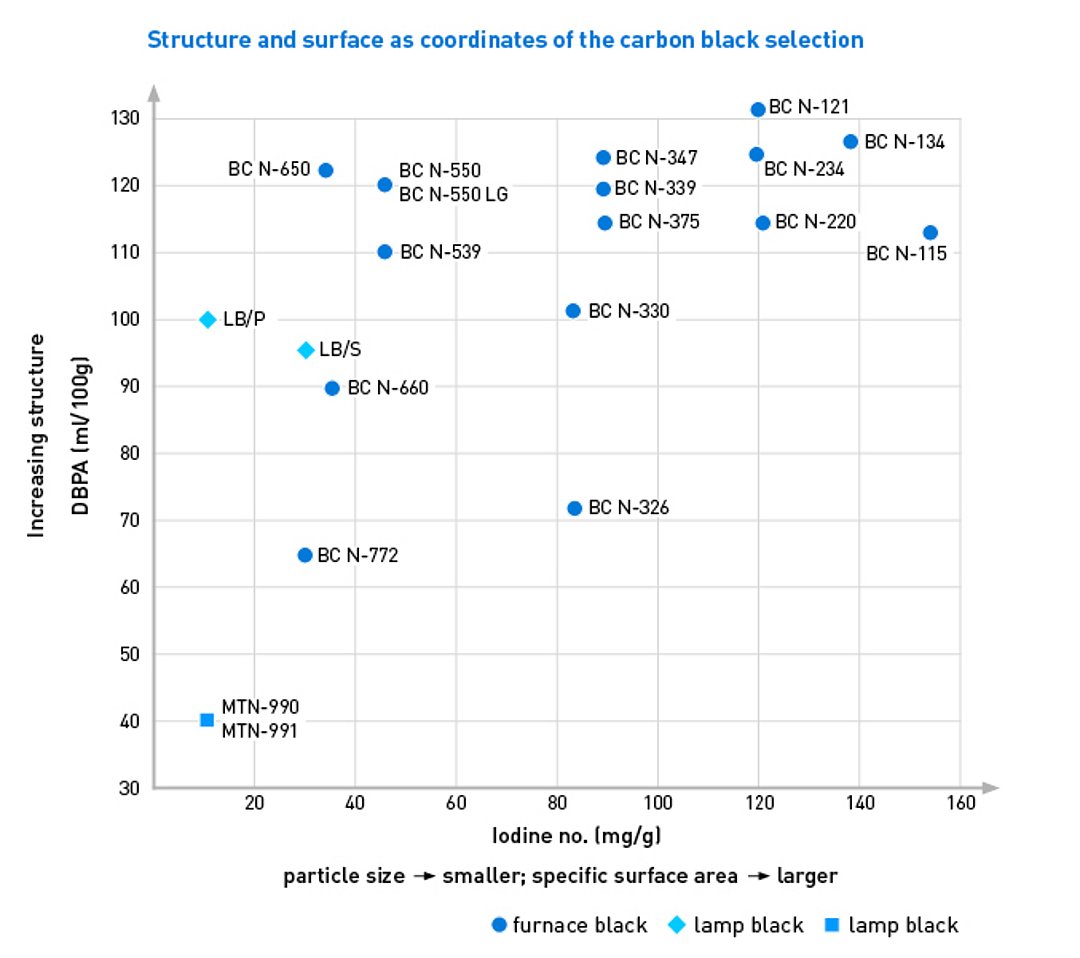

The influence of “structure”, particle size and surface

Structure increases =

- viscosity increases

- hardness increases

- modulus increases

- elongation at break decreases

- swelling after extrusion decreases

- dispersibility increases

- impact resilience remains constant

- tensile strength unaffected

- compression set/permanent set characteristics remain constant

Particle size decreases, specific surface area increases =

- viscosity increases

- hardness increases

- modulus remains constant

- elongation at break decreases slightly

- swelling after extrusion remains constant

- dispersibility decreases

- impact resilience decreases

- tensile strength increases

- compression set/permanent set characteristics increase